1 广东工业大学 机电工程学院 激光微纳加工研究中心, 广州 510006

2 广东工业大学 实验教学部, 广州 510006

为了使用低成本的红外光纤激光器对蓝宝石进行高效率高质量的加工, 采用激光诱导背向湿式刻蚀方法进行了理论分析和实验验证, 研制了一种新型的活性高且稳定性高的混合溶液, 硫酸铜的质量浓度为28g/L、次磷酸钠的质量浓度为40g/L、氨水的质量浓度为45g/L、pH值为12。在相同的加工条件下, 采用硫酸铜水溶液和混合溶液对蓝宝石进行切割。结果表明, 蓝宝石在混合溶液中的切割效率高出硫酸铜水溶液中的5倍左右; 采用混合溶液对蓝宝石进行成形切割, 加工出了高质量的异形蓝宝石零件。此研究对提高低功率激光作用下蓝宝石的加工效率有一定的指导意义。

激光技术 混合溶液 激光诱导背向湿式刻蚀 蓝宝石 成形切割 laser technique mixed working solution laser-induced backside wet etching(LIBWE) sapphire forming cutting

Author Affiliations

Abstract

1 Laser Micro/Nano Processing Lab, School of Electromechanical Engineering, Guangdong University of Technology, Guangzhou 510006, China

2 Department of Experimental Teaching, Guangdong University of Technology, Guangzhou 510006, China

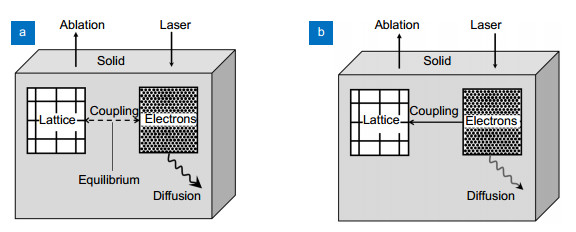

Transparent brittle materials such as glass and sapphire are widely concerned and applied in consumer electronics, optoelectronic devices, etc. due to their excellent physical and chemical stability and good transparency. Growing research attention has been paid to developing novel methods for high-precision and high-quality machining of transparent brittle materials in the past few decades. Among the various techniques, laser machining has been proved to be an effective and flexible way to process all kinds of transparent brittle materials. In this review, a series of laser machining methods, e.g. laser full cutting, laser scribing, laser stealth dicing, laser filament, laser induced backside dry etching (LIBDE), and laser induced backside wet etching (LIBWE) are summarized. Additionally, applications of these techniques in micromachining, drilling and cutting, and patterning are introduced in detail. Current challenges and future prospects in this field are also discussed.

transparent brittle materials glass sapphire laser machining Opto-Electronic Advances

2019, 2(1): 180017